Learn more

| Format | 25 kg sack |

|---|---|

| Composition | Powder |

| Average consumption | 3 - 5 kg/m2 |

| Conservation | 12 months in a dry place and in the packaging provided by us. |

| Opening time | 30 minutes |

| Technical data sheet | Download the tech spec |

| Tutorial | Watch the tutorial |

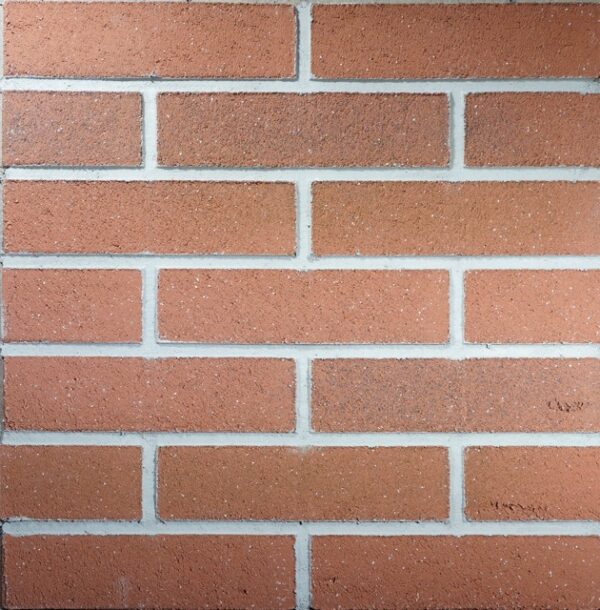

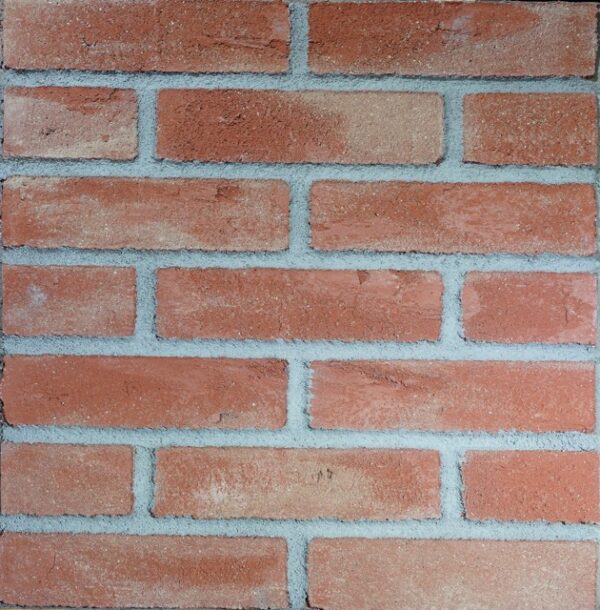

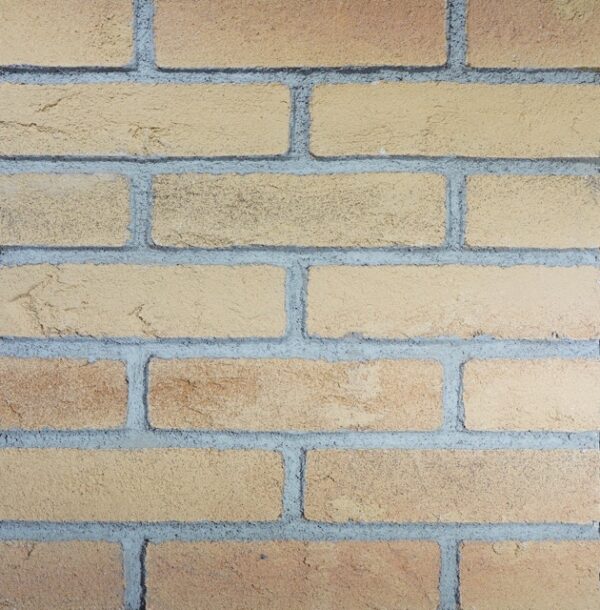

Our coverings

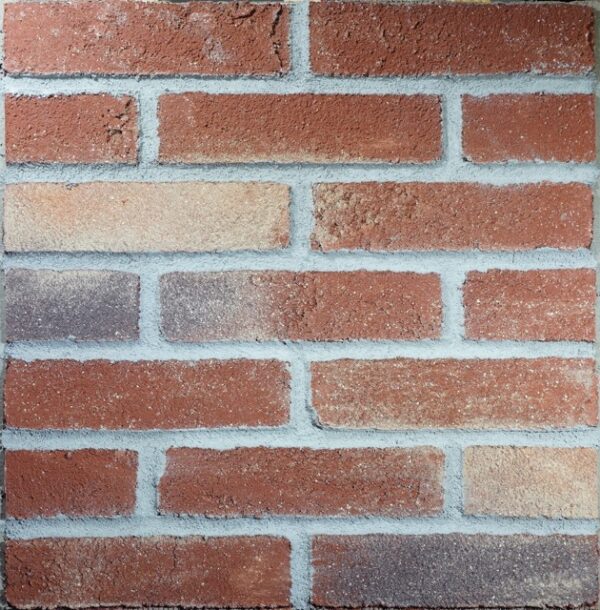

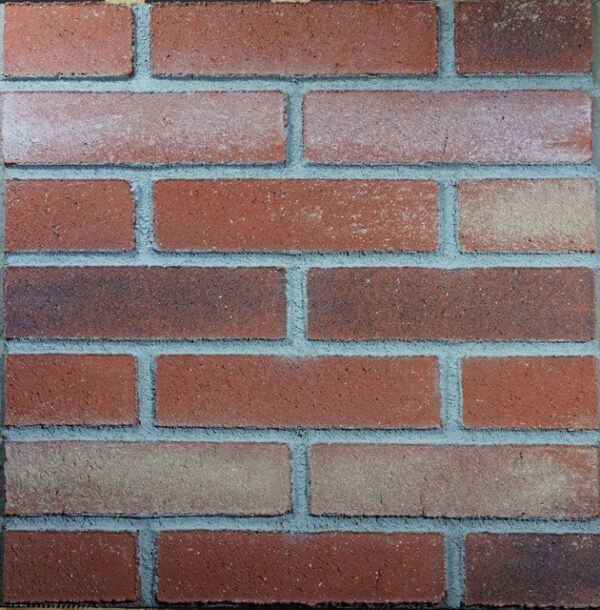

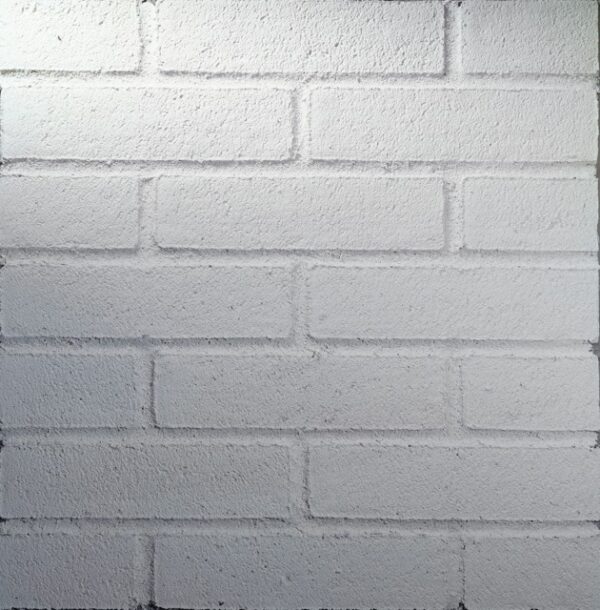

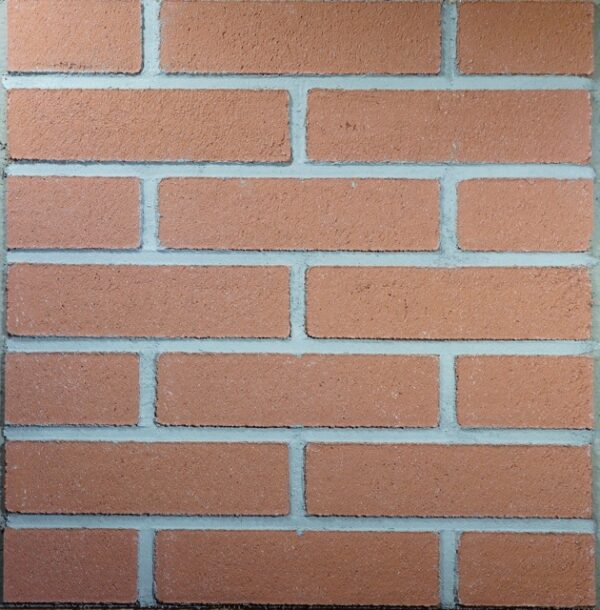

From pale shades to intense red, our range of brick veneer offers the perfect color solution for every style. Discover all the color options, from the elegance of white brick veneer to the modernity of gray brick-effect veneer.

Simple, quick and clean installation!

In just a few steps, you can create a durable and long-lasting brick-effect covering, without any invasive work.

Flex 019: flexible powder adhesive for safe installation

Flex 019 is the flexible and long-lasting cementitious adhesive ideal for multiple installation projects, guaranteeing secure and long-lasting adhesion.

Where to apply glue powder

Flex-019 powder is the ideal ally for multiple installation projects, guaranteeing long-lasting and secure adhesion.

Interior/Exterior

For applications on substrates such as plaster, plasterboard, scagliola or anhydrite screeds.

Wet Areas

For installation in bathrooms, shared showers and environments subject to high humidity, thanks to its high water resistance.

Insulating Materials

For bonding insulation panels (polystyrene, expanded polyurethane, rock wool, glass wool, cork) on absorbent substrates.

Special Supports

For applications on substrates such as plaster, plasterboard, scagliola or anhydrite screeds.

When NOT to use glue powder

There are some situations in which Flex-019 powder adhesive should not be used to prevent detachment and structural failure.

Unstable/Uncured Substrates

Do not apply to fresh screeds or substrates that have not completed hygrometric shrinkage and curing.

Metals

Not suitable for installation on metals without the use of a specific and compatible primer.

Moisture-sensitive Substrates

On materials such as wood or wood-based materials, always consider using epoxy/polyurethane adhesives or specific cementitious adhesives.

Complete installation guide: preparation and application of Flex 019

Correct installation and durability of the covering require compliance with the following phases:

1. Preparation of the support

The substrate must be clean, solid, cured, and free of contaminants (dust, oil, paint). Prime highly absorbent substrates to prevent rapid absorption.

2. Mixing the glue powder

Prepare the glue by adding 6-7.5 liters of water to each 25 kg bag. Mix (drill at low speed) until smooth. Let sit for 5 minutes (maturing).

3. Product layout

Apply the product with a notched trowel (5 mm to 10 mm) on the substrate.

4. Quick Check: Finger Test

To check workability, touch the glue once it's spread. If there's residual glue on your finger, it's still workable. If a "skin" (dry film) has formed, adhesion is compromised; remove the glue and apply fresh product.

5. Removing the excess

Any excess glue seeping from the joints or onto the surface of the Mattonflex must be removed immediately with a damp sponge. Once hardened, the glue can be very difficult and damaging to remove.

Common mistakes to avoid with Flex 019 powder

To maximize the performance of Flex 019 powder and avoid adhesion or degradation problems, it is essential to strictly follow the operating instructions. The following guidelines address the most common application errors that can compromise the work.

Revive expired dough

Don't add water to revive the mixture once it begins to harden (it exceeds its pot life). Discard the hardened glue.

Wrong temperature

Do not apply at substrate/ambient temperatures below +5°C or above +35°C.

"Point" pose

The tile must be laid in a full bed. Do not lay with simple dots of glue: this is an unacceptable method that does not guarantee durability.

Getting through the open time

Respect the working open time. The formation of a "skin" compromises adhesion.

Products for laying the covering

To complete the installation, you can use specific Mattonflex primers and adhesives. These products are designed to ensure maximum adhesion and long-lasting durability of your flexible brick cladding.

Certifications

Mattonflex offers only CE-marked products, compliant with European standards for construction materials. Tested for strength, adhesion, water absorption, and thermal stability (UNI EN 14411, 14617-5, 14617-15, 15285), they guarantee quality, safety, and durability. Consult the technical data sheets to discover all the certifications.

FAQ

Flex-019 paste is ready to use. Simply open the jar and stir briefly with a trowel before use. The product is a creamy paste that is easy to spread with a trowel, but with excellent thixotropy. Once the application is complete, any leftover product can be stored in the tightly closed jar for later use.

Apply a thin layer of Flex-019 paste to the substrate with a notched trowel, using the amount of adhesive necessary to ensure correct application.

Consumption: 4 kg/m² with a 6 mm trowel.

Translated with DeepL.com (free version)

- Indoor and outdoor wall installation suitable for Mattonflex.

- Installation of polystyrene, polyurethane foam, rock wool, glass wool and cork insulation panels on absorbent substrates.

- Suitable for installation in damp environments such as bathrooms and communal showers.

- Applications on plaster, plasterboard, scagliola or anhydrite screeds.

Under standard conditions (approximately 23°C and 50% humidity), drying times are 24/48 hours.

- Cement-based plaster: for wall coverings.

- Concrete: provided it is cured (usually at least 6 months) to prevent shrinkage that could crack the tiles.

- Mixed mortars: classic mixtures of sand, cement and lime.

- Overlaying other tiles: you can lay new tiles over old ceramic, marble or natural stone tiles (after thorough degreasing).

- Heated screeds: thanks to their elasticity, they resist the thermal shocks of radiant pipes.

- Waterproofing: they can be applied directly over elastic membranes (such as the Kedilastic or Isolflex line by Kedil), typically in showers, balconies and swimming pools.

- Swimming pools and tanks: they resist constant immersion.

- Plasterboard, insulating cladding.

Notched trowel

5 / 6kg/mq

It is a tile adhesive that can be used for almost all types of coverings. For more information, contact us by email at info@mattonflex.it.